- Home Page

- Company Profile

-

Our Products

- Safety Switches

- Conveyor Zero Speed Switch

- Control Instruments

- Damaged Belt Detector Rope Type Safety Switches

- Missing Bucket Detector

- Belt Misalignment Sensor for Bucket Elevator

- Belt Sway Switch

- Flameproof Pull Cord Switch

- Heavy Duty Limit Switch

- Zero Speed Switch

- Compact Zero Speed Switch

- Belt Watch System

- Cement Bag Counter

- Conveyor Safety Switches

- Belt Sway Switch with Junction Box

- Safety Interlock Switches for Bucket Elevetor

- Cable Pull Safety Switches

- Safety Light Curtain Controller

- Pull Cord Switches for Indoor Machines

- Pull Cord Guard Sensing Safety Switch

- Pull Cord Switch With Terminal Strip

- Pull Cord Switch with Reset Lever

- Pull Cord Safety Switch With Junction Box

- Safety Pull Cord Switches

- Pull Cord Switch with Reset Button

- Digital Zero Speed Switch

- Pull Safety Switch

- Pull Cord Switch with Mechanical Flag

- Level Switches

- Proximity Switch

- Inductive Proximity Switch

- Photoelectric Proximity Switches

- Magnetic Proximity Switch

- Analog Output Inductive Proximity Switch

- Linear Output Inductive Proximity Switch

- Analogue Inductive Proximity Switch

- Cylinder Position Sensor Magnetic Switch

- Ultrasonic Proximity Sensor Switch

- Capacitive Proximity Switches

- Indicating & Controlling Instruments

- Level Management Solutions

- Signal Conditioning

- Promixity Switches

- Agency Products

- Safety Switches

- Contact Us

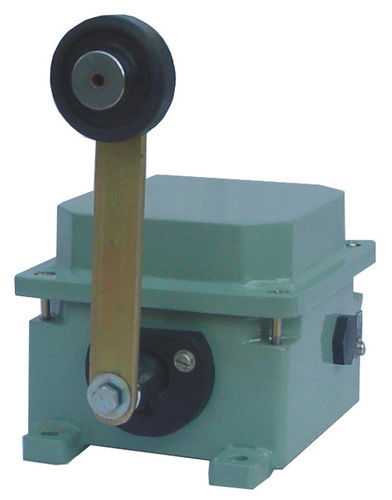

Belt Misalignment Sensor for Bucket Elevator

14300 INR/Piece

Product Details:

- Power Supply 230 V AC

- Output 2 NO + 2 NC

- Usage Belt Misalignment Sensor for Bucket Elevator

- Input From Sensor

- Product Type BMD

- Application Industrial

- Rated Voltage 230 Volt (V)

- Click to View more

X

Belt Misalignment Sensor for Bucket Elevator Price And Quantity

- 14300 INR/Piece

- 1 Piece

Belt Misalignment Sensor for Bucket Elevator Product Specifications

- 2 NO + 2 NC

- BMD

- 8 Kilograms (kg)

- 230 V AC

- Belt Misalignment Sensor for Bucket Elevator

- 230 Volt (V)

- From Sensor

- Industrial

- 1 Year

- Belt Misalignment Sensor for Bucket Elevator

Belt Misalignment Sensor for Bucket Elevator Trade Information

- Pune

- Cash in Advance (CID)

- 50 Piece Per Week

- 1-2 Week

- Contact us for information regarding our sample policy

- Export Worthy

- Western Europe, Australia, North America, Eastern Europe, Central America, Middle East, South America, Asia, Africa

- All India

- Internal TC

Product Description

Salient Features:

1.No physical contact

2.No wear and tear, hence long life.

3.Switches for use in hazardous locations are also available.

4.High sensing range

5.No effect of dust, water and mud hence reliable operation

Specification:

Supply: 10-30 V DC

O/P: PNP or NPN, NO + NC

Load current: 200 mA

Size: Rectangular Block type with mounting bracket and gasket

Object sensed: Any Ferromagnetic minimum size 150 x 150 x 2 mm

Sensing Range: Up to 80 mm

Max operating frequency: 100 Hz

Operating Temp: 70 degree cent

Enclosure: ABS Plastic , IP 67

Additional power supply working at 230 V AC and with latching circuit with local reset push button available.

| Country of Origin | Made in India |

| Ip Rating | IP 65 |

| Operating Temperature | 80 degree |

| Rated Impulse Withstand Voltage | 1500 V |

| Rated Insulation Voltage | 1500 V |

| Utilization Category | Field Mounting, Conveyor Safety |

| Contact Type | Snap Action, 2 NO + 2 NC, 1 NO + 1 NC |

| Housing Material | Cast Al |

| Certification | Enclosure Grade |

| Material/Body | Metal |

| Model Name/Number | BMS |

| Switch Type | Weatherproof |

| Power/Voltage | 230 VAC |

| Sensor Type | Belt Misalignment |

| Current Rating | 5 AMP |

| Part Number | BMS |

| Brand | Smartsaa |

| Features | Snap Action |

FAQs of Belt Misalignment Sensor for Bucket Elevator:

Q: What is the function of the Belt Misalignment Sensor for Bucket Elevator?

A: The function of the Belt Misalignment Sensor for Bucket Elevator is to detect the misalignment of the belt in the bucket elevator and send an alert signal to the control system to prevent any damage to the equipment.Q: What is the rated voltage of the Belt Misalignment Sensor for Bucket Elevator?

A: The rated voltage of the Belt Misalignment Sensor for Bucket Elevator is 230 Volt (V).Q: What is the power supply requirement for the Belt Misalignment Sensor for Bucket Elevator?

A: The power supply requirement for the Belt Misalignment Sensor for Bucket Elevator is 230 V AC.Q: What is the weight of the Belt Misalignment Sensor for Bucket Elevator?

A: The weight of the Belt Misalignment Sensor for Bucket Elevator is 8 Kilograms (kg).Q: What is the warranty period for the Belt Misalignment Sensor for Bucket Elevator?

A: The warranty period for the Belt Misalignment Sensor for Bucket Elevator is 1 year.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese